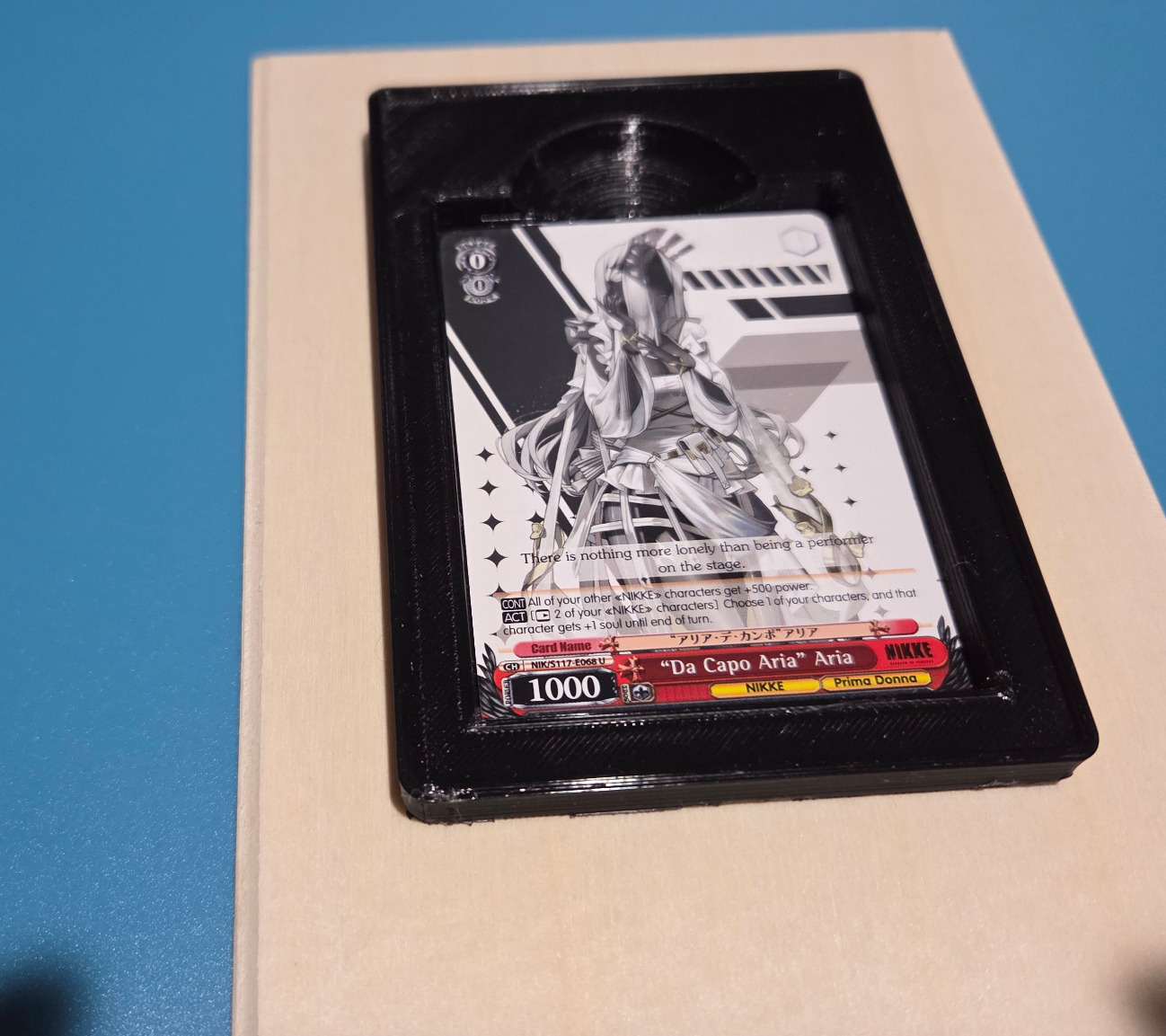

For today, I worked on a STL file and modified it to be a shallow card jig for making consistent layers for the shadowboxed cards after they are cut and ready to be glued together. It should make for a more consistent/professional look. I also added a small block of wood and mounted it underneath the card jig for more stability as I am working on alignment.

For this jig, it will hold approximately six cards with cardstock spacers sandwiched in between. I believe this will be a good thing to have when mass producing shadowbox cards for selling. They'll be consistently produced with minimal errors. In my other post, I 3d printed some six card shadowboxes that will be a more premium looking end result.

I will be sending out some work to a friend who has a resin 3d printer to make some more shadowbox card holders and a modified card holder to a 5x7 size for making homage versions of cards. I'll be testing out some scanning and enlarging cards with printing at the 5x7 size and eventually building out some larger shadowboxes.

For this jig, it will hold approximately six cards with cardstock spacers sandwiched in between. I believe this will be a good thing to have when mass producing shadowbox cards for selling. They'll be consistently produced with minimal errors. In my other post, I 3d printed some six card shadowboxes that will be a more premium looking end result.

I will be sending out some work to a friend who has a resin 3d printer to make some more shadowbox card holders and a modified card holder to a 5x7 size for making homage versions of cards. I'll be testing out some scanning and enlarging cards with printing at the 5x7 size and eventually building out some larger shadowboxes.